| |

HOW

TO BE AN 'INFORMED BUYER' OF SOCCER BALLS |

|

|

| |

|

|

| |

We

try our best to provide our customers and

general people essential information about

sports and equipment. The soccer ball buyer’s

guide is one effort to make soccer and sports

ball buyers more informed in their decision.

This guide about the soccer ball parts,

production process and material characteristics

can be followed as an example for the most

of other inflatable sports balls but exceptions

exist. This section includes the following

parts:

|

|

| |

| |

|

|

| |

|

|

|

| |

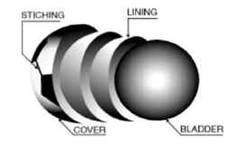

The

four main components of a soccer ball are

the cover, the lining, the stitching, and

the bladder. Understanding these components

and their options will help you in choosing

the perfect ball to meet your playing and

quality needs. |

|

| |

|

|

| |

|

| |

| |

Elements

of Soccer Balls and Materials used in Production |

|

| |

|

| - |

Surface, Casing or Cover |

|

| - |

Internal

Linings (Polyester or Cotton) |

|

- |

Stitching

|

|

- |

Bladder

(Latex or Butyl) |

|

|

|

|

|

|

| |

|

|

|

| |

The

ball cover consists of synthetic or artificial

leather or PU laminated splits. Various

types of synthetic leather are used in the

outer covering of ball for producing different

qualities and this becomes a determining

element in pricing. The cover material also

determines the performance of sports balls

in various playing conditions. The playing

condition could affect the durability, flight

and drive of ball during play.

The surface of soccer balls or coverings

is made up from synthetic leather. Synthetic

leather is typically made from PU (polyurethane)

and PVC (poly vinyl chloride). There are

many variations of synthetic leather used

in the construction of soccer balls. They

range from AI-2000, Japanese Teijin Cordley,

Microfiber, English Porvair, Korean Ducksung,

Leather Art Pakistan Synthetic Leather,

and PVC (poly vinyl chloride). Therefore,

special attention is given to use material

which could withstand environment such as

water, extreme heat, sun exposure, cold

weather, rough surface, abrasion, etc.

The top quality soccer balls used in competition

matches and by professionals are produced

by using AI-2000, Cordley, Ducksung, Mircofiber

or other types of PU synthetic leather,

giving ball the balls superior feel and

softness, durability, fine finish and maneuverability.

Promotional soccer balls or practice balls

are usually constructed with Polyvinylchloride

(PVC) or rubber stitched covers that give

soft feel, durability, scuff and water resistant

qualities.

Some indoor soccer ball covers are made

with a felt material similar to what is

used on a tennis ball.

The polyvinyl chloride (PVC) is often used

for lower end price models and is therefore

not long lasting. It is affordable and enjoyable

for leisure time. PVC cover material is

scuff and water resistant. It tends to be

harder and heavier and thus offers less

feel and softness.

The cover material may have a clear finish

of enamel or gloss and matt on the materials.

|

|

| |

|

|

| |

Printing |

|

|

| |

The

printing is done by penetrating the ink

in the covering material of the ball. Any

brand names, logos and graphics are printed

on the panels at this stage. Printing is

typically accomplished by silk-screening

printing process. A special transparent

top coating may be applied on surface of

the designs and printing to protect and

make them supportable. |

|

| |

|

|

| |

Lining |

|

| |

The

process of placing multiple layers of polyester

and/or cotton which is bonded (laminated)

together is called lining or lamination of

soccer balls cover material to produce a tough,

smooth exterior. Material thickness plays

a vital part in the quality of hand-sewn soccer

balls as it endures the power of kick along

with the bladder of ball. The lining gives

the ball strength, structure, feel, control

and helps the ball to retain its shape and

bounce over the life of the ball.

The lamination or lining of synthetic leather

shell with strongest cross laminated layers

of fibre is carried out by using natural

latex adhesives. The anti fungus ingredients

are blended into condensed natural latex

adhesive to make ball fungus-proof.

Professional soccer balls usually have

four or more layers of lining. Mid-level

balls generally are comprised of two or

three layers of cotton and polyester layers

of lining. Lower-priced balls generally

are constructed of two layers of polyester.

Promotional or practice balls are often

constructed with less layers of lining.

Many soccer balls include a foam layer for

added cushioning and ball control.

|

| |

|

|

| |

Stitching |

|

|

| |

The

stitching is performed by turning the ball

inside out, so none of the stitches show

on the outside. Hand sewn balls have tighter

and stronger seams. The highest quality

balls are hand-stitched with polyester cord

or similar thread. The nylon waxed twine

is also used to prevent water intake. 5-ply

twisted polyester cord is the material of

choice in stitching together a soccer ball.

Kevlar® reinforced polyester stitching

is also used on some balls. |

|

| |

|

|

| |

Panels |

|

|

| |

The

number of panels -- the different segments

that make up the outside covering of the ball

-- varies for each design.

A 32 panel ball is most common and other

includes 26, 18 panels used in various professional

leagues. Other variations may include 20

hexagonal, 12 pentagonal surfaces. Fewer

panels generally mean the ball can be curved

more when kicked because of less stability

to the cover. |

| |

|

|

| |

Bladder |

|

|

| |

The

bladder is the inside part of the ball that

is filled with air. Generally two types

of bladders are used in sports balls - latex

bladder and butyl bladder. |

|

| |

|

|

| |

Latex

Bladder |

|

| |

The

latex bladders offer the softest feel, response

and surface tension but do not provide the

best air retention. They generally require

more frequent filling up with air. |

|

| |

| |

Butyl

Bladder |

|

| |

The

butyl bladders retain air for longer periods

of time and offer the excellent combination

of contact quality and can be found in most

middle to upper priced balls.

Futsal ball bladders are filled with foam

to limit the bouncing capability of the

ball since they are used on hard flooring. |

|

| |

|

|

| |

Bladder

Variations |

|

| |

There

are some variations in bladders which deals

with the short comings in the above two

types of bladders, especially the air retention

quality. |

|

| |

|

|

| |

|

1.

The latex bladder with butyl valves is used

for longer air retention and to prevent the

warping of balls. |

|

| |

|

2. In the higher

end balls, silicone-treated valve is used

for superior performance. The silicone liquid

is applied to nourish

and lubricate the valve for air control. |

|

| |

| |

|

|

| SOCCER

BALL SIZES |

|

| |

Soccer

balls come in the following official sizes:

|

|

| |

|

|

| |

|

| - |

Size 5 Ages 12 and up |

|

| - |

Size 4

Ages 8 and 12 years |

|

- |

Size 3

Under 8 years |

|

- |

Size 2

and 1 Promotional soccer balls |

|

| |

|

|

|

| |

Many

soccer leagues have different size requirements,

so be sure to check with your coach or organization

to find out which is the proper size for the

age group that the ball will be used with.

|

|

| |

|

|

| |

Size

3: |

|

| |

- |

Size 3 balls

are the smallest balls and are generally used

for children under the age of 8 |

|

|

- |

These balls are

generally 23-24 inches in circumference and

weigh between 11-12 ounces |

| |

| Size

4: |

|

Size 4 balls

are used for players between the ages of 8-12

|

|

|

Size 4 balls

weigh between 12-13 ounces and have a circumference

of 25-26 inches |

| |

| Size

5: |

|

This is the international

standard match ball for all ages 12 and older,

including all adult play |

|

The size 5 ball

weighs between 14-16 ounces with a circumference

of 27-28 inches |

|

| |

|

|

| PACKAGING

MATERIAL |

|

| |

The

soccer and sports balls are packed in strong

cartons to withstand the stress of journey.

The printing or marking, handling instructions

on inner carton, if any, outer cartons and

poly bags are neatly carried out.

There is variety of material available

for packaging solution. The packing material

approved by customers is used for packing

of balls. |

|